Urethane elastomers have various advantages when compared with rubber, plastic and metal. This is especially true in regard to the urethane elastomers made using our product Tolidine diisocyanate (TODI). TODI-based elastomers offer excellent heat and hydrolysis resistance, along with superior mechanical properties.

Concerning the manufacturing point of view, due to its longer pot life, TODI-based prepolymer is easier to handle in comparison to NDI-based products.

Technical Information:

Physical and Chemical Properties

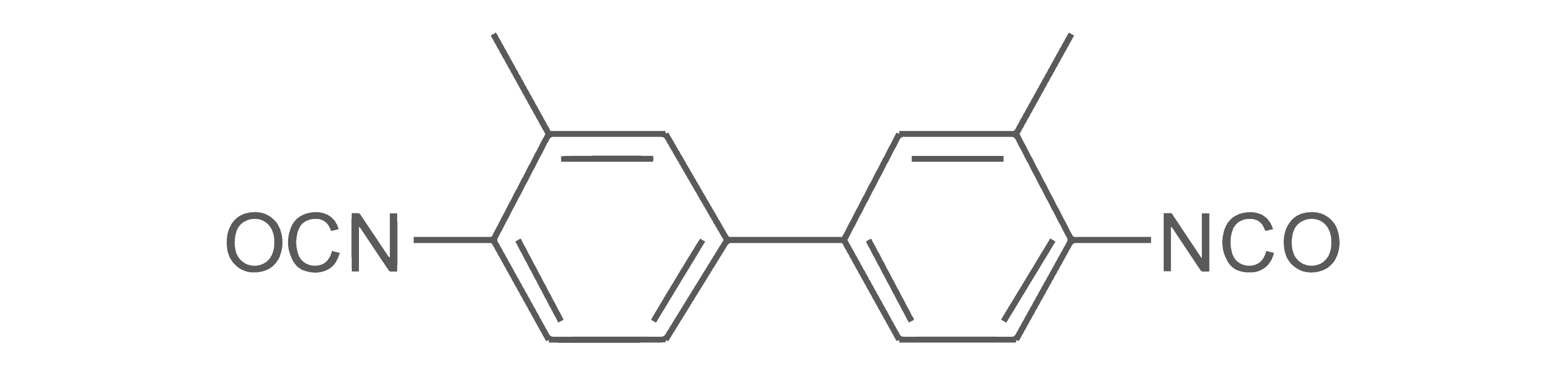

| Name | TODI (CAS No: 91-97-4) 4,4’-Diisocyanato-3,3’-dimethyl-1,1’-biphenyl |

| Synonyms | 3,3’-Dimethyl-4,4’-biphenyldiisocyanate O-Tolidine diisocyanate |

| Purity | Min. 99.5% |

| Molecular Weight | 264.286 g/mol |

| Package | 50 kg Fiber drum with inner plastic bag |

| Storage | Keep cool and dry place |

| Appearance | White pellets |

| Odor | Odorless |

| Boiling Point | 195-197°C (5 mmHg, or 667 Pa) |

| Melting Point | 71.7°C |

| Specific Gravity | 1.197 (80°C) |

| Solubility | Insoluble in water and slowly hydrolyzed by water. Soluble in aceton, carbon tetrachloride, kerosene, benzene, chlorobenzene, nitrobenzene. |

| Flash Point | 218°C (cleveland open cup) |

| NCO Content | 31,78 2 x 42 (-NCO)/264.286 x 100 |

APPLICATIONS

-

Sealing (Oil sealing, piston ring, water sealed, etc.)

-

Hydrophobic hydrocarbon main chain

-

Automobile parts (Grille, shock absorbers, bumper extensions, etc.)

-

Industrial use (Belt, roll, caster, etc.)

-

Electric (Coating agent, etc.)

-

Medical equipment (Artificial organ, etc.)

Chemical Structure